In the metal heat treatment process, quenching oil plays a crucial role, especially during the quenching phase, where effective temperature control of the oil is essential for ensuring the quality and performance of the metal. Real Tern Industrial Co., Ltd. specializes in providing efficient finned tube heat exchangers designed to meet the cooling demands of quenching oil applications.

Application Needs

The quenching process can cause the temperature of the quenching oil to rise rapidly. Excessive oil temperatures can adversely affect the quenching results, leading to deformation or cracking of the metal. Therefore, to ensure the stability of the quenching process and the quality of the metal parts, an efficient cooling system must be employed to lower and control the temperature of the quenching oil.

Product Features

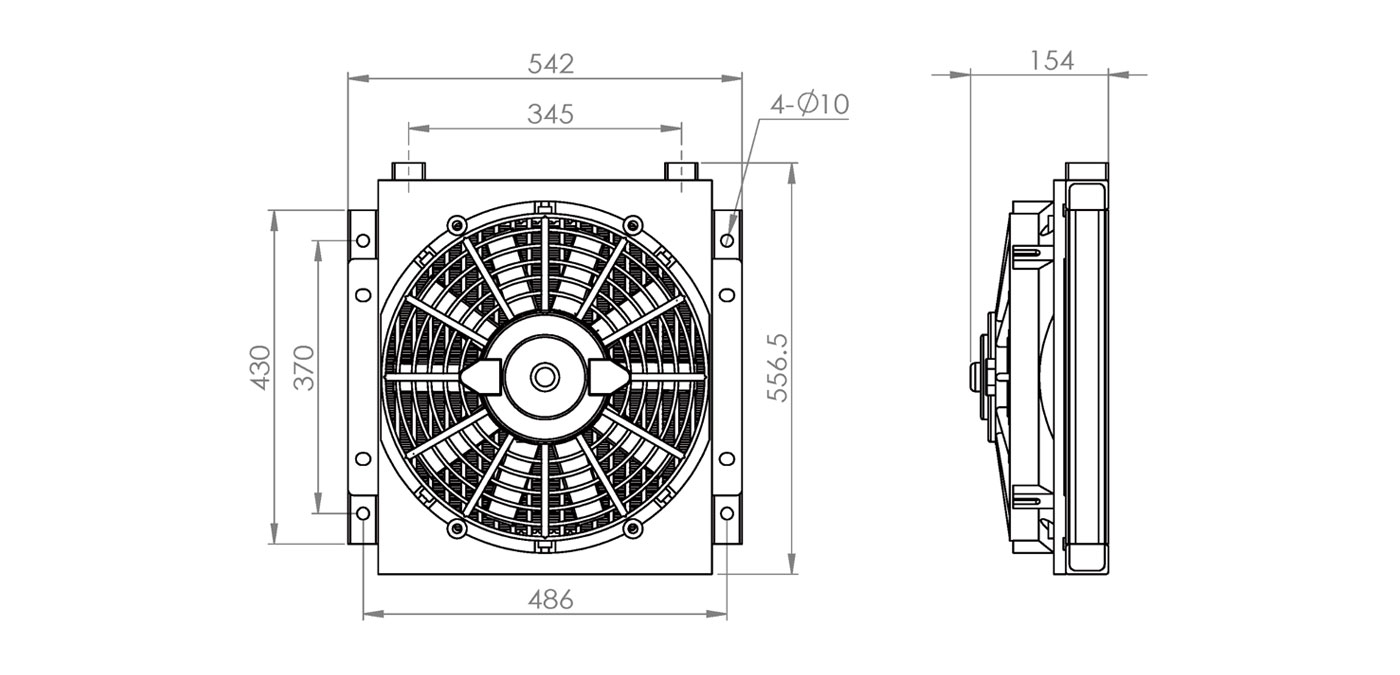

High Heat Exchange Efficiency: The design of our finned tube heat exchangers maximizes the heat transfer surface area, allowing for rapid dissipation of heat from the quenching oil to the surrounding environment, keeping the oil temperature within optimal ranges.

High-Temperature and Corrosion Resistance: Our heat exchangers are constructed from materials that are resistant to high temperatures and corrosion, ensuring long-term stable operation during the quenching process, thereby guaranteeing equipment reliability and durability.

Flexible Configuration: Finned tube heat exchangers can be customized to meet the specific requirements of different quenching systems, accommodating various tank sizes and operational environments, facilitating integration into existing setups.

Reduced Energy Consumption: Through effective thermal management, finned tube heat exchangers can lower the energy consumption required for cooling, enhancing overall energy efficiency.

Easy Maintenance: The design of our heat exchangers allows for convenient maintenance, making regular cleaning and inspections straightforward, which helps reduce maintenance costs.

Application Cases

Metal Processing Plants: In metal processing plants, finned tube heat exchangers are utilized to cool quenching oil, ensuring that the oil temperature remains within optimal ranges during the quenching process, thereby improving the structural integrity of the metal.

Heat Treatment Furnaces: In heat treatment furnaces, the use of finned tube heat exchangers effectively lowers the temperature of quenching oil, ensuring uniform cooling of metal parts during the heat treatment process and reducing the risk of deformation.

Mold Quenching: During mold quenching processes, finned tube heat exchangers can rapidly remove heat from the oil, protecting molds from overheating and extending their lifespan.