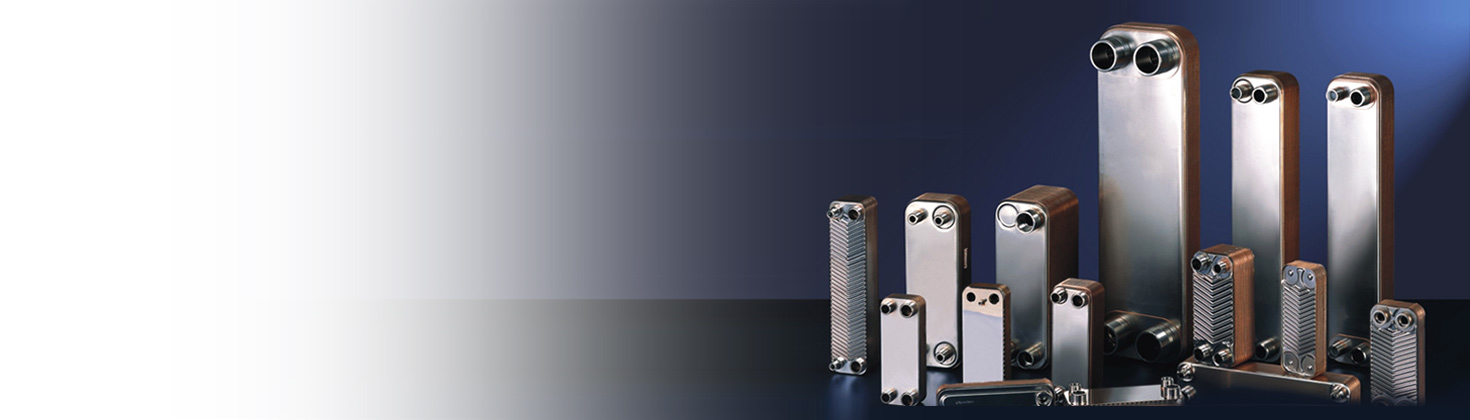

Finned tube heat exchangers are devices that increase the surface area for heat transfer by incorporating fins. They typically consist of a series of tubes with attached fins that facilitate the transfer of heat between a hot fluid and a cold fluid. The working principle relies on the conduction of heat between the two fluids flowing in parallel or at angles to each other, allowing for effective energy transfer.

These heat exchangers are widely used in applications such as air conditioning, industrial cooling, and power generation. Their design can enhance heat exchange efficiency, making them suitable for various environmental conditions. Depending on the materials and fluid characteristics, finned tube heat exchangers can offer excellent corrosion resistance and thermal conductivity, playing a crucial role in energy conservation and system efficiency improvement.

-

OA Series

Driven fans oil coolers with AC, DC power, outer rotor motor and electric motor predisposition.

Maintenance: To ensure the cooler operates at maximum efficiency, please perform regular maintenance.

Use high-pressure air to periodically clean the external cooling fins. If a cleaning solution is needed, use a neutral detergent, and make sure the cooler is dry before starting operation.

-

RT Series

Driven fans oil coolers with AC, DC power, outer rotor motor, electric motor and hydraulic motor predisposition.

The series is designed specifically for European standards. The oil cooler's dimensions, port threading, mounting, fan motor (ie. DC driven, axial fan, electric motor, hydraulic motor) are spec'd as per EU standard.

The oil cooler core is made with aluminum finned tubes attached, in order to increase the surface area available for heat transfer.