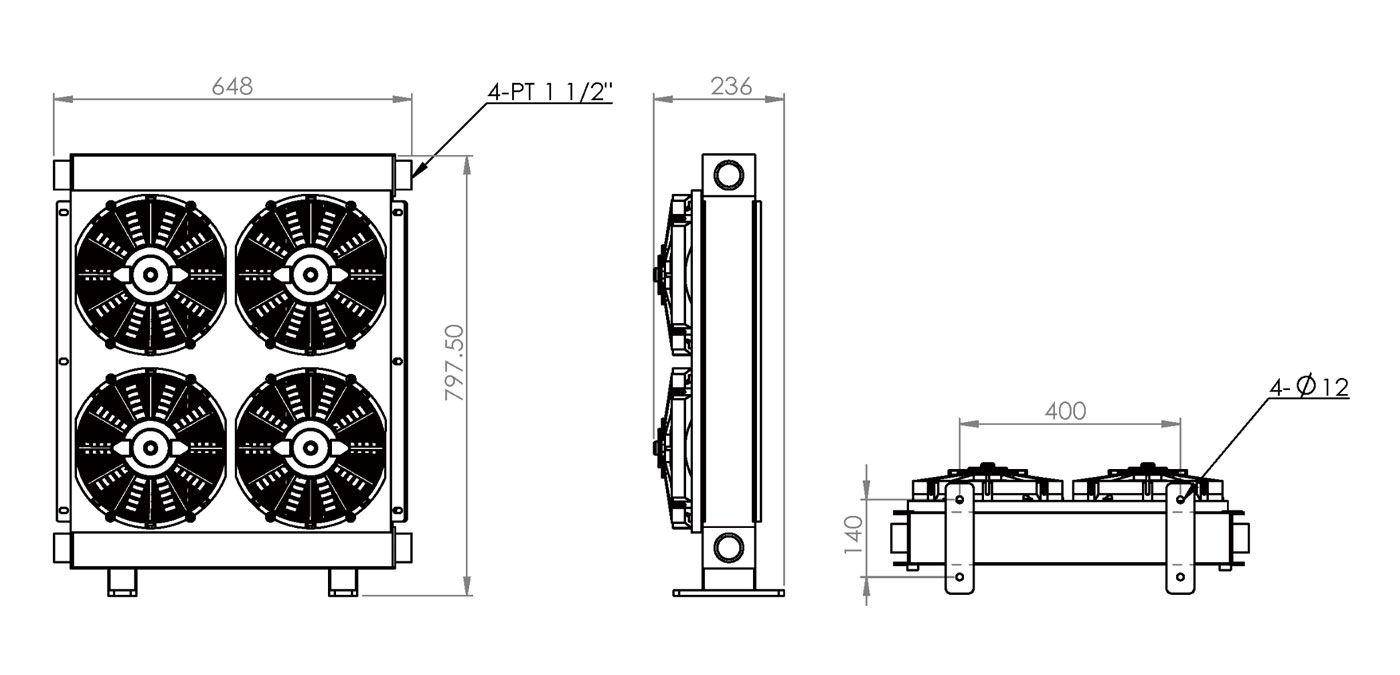

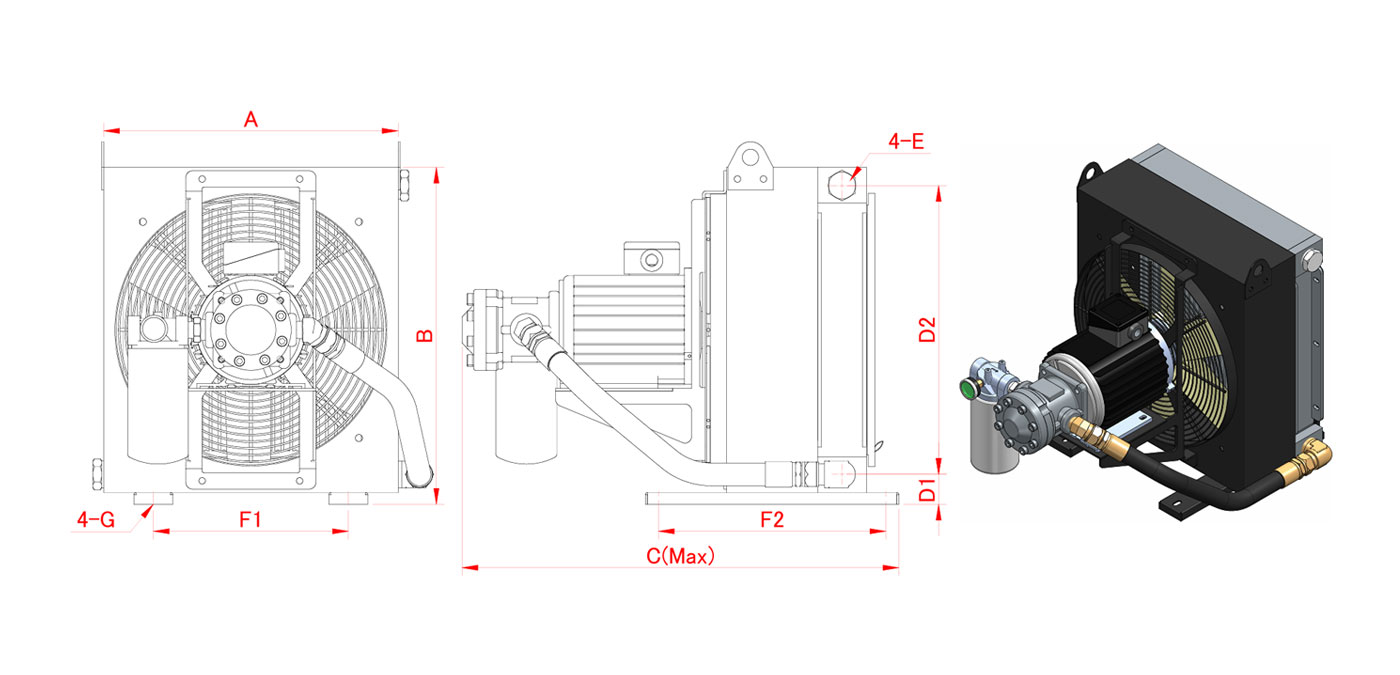

In the mining industry, effective cooling solutions are essential to ensure the reliable operation of mining servers and equipment. Real Tern Industrial Co., Ltd. offers specialized finned tube heat exchangers designed to meet the demanding cooling needs of mining applications.

Cooling Requirements

Mining operations involve heavy machinery that generates significant heat during prolonged use. This heat must be effectively dissipated to prevent overheating, which can lead to equipment failures, decreased efficiency, and costly downtime. Finned tube heat exchangers provide an efficient solution for managing heat in various mining equipment, including drill rigs, haul trucks, and crushing machines.

Product Features

High Heat Exchange Efficiency: The design of our finned tube heat exchangers maximizes the surface area for heat transfer, enabling rapid and efficient cooling of mining equipment. This is crucial in maintaining optimal operating temperatures, especially in high-load conditions.

Durable Construction: Our heat exchangers are built using robust materials designed to withstand the harsh environments typical of mining operations. They resist abrasion, corrosion, and extreme temperatures, ensuring long-lasting performance even in the most challenging conditions.

Customizable Design: We understand that different mining applications have unique cooling requirements. Our finned tube heat exchangers can be customized in size, configuration, and material selection to fit specific machinery and operational needs.

Compact and Lightweight: The compact design of our heat exchangers allows for easy integration into existing equipment without adding significant weight. This is particularly beneficial in mobile mining machinery where weight distribution is critical.

Ease of Maintenance: Designed for accessibility, our heat exchangers facilitate straightforward maintenance and cleaning, reducing downtime and operational disruptions in the field.

Application Cases

Drilling Equipment: Finned tube heat exchangers can effectively cool hydraulic systems in drilling rigs, preventing overheating and ensuring smooth operation during extended drilling cycles.

Haul Trucks: In haul trucks, these heat exchangers help maintain optimal engine temperatures, enhancing performance and fuel efficiency while prolonging engine life.

Crushing Machines: For crushing machinery, finned tube heat exchangers provide reliable cooling for the hydraulic and lubrication systems, minimizing wear and tear on components.